For people who manufacture or produce plastic products on a frequent basis, molding is an integral part of their operations. Molding can be termed as a process of fabrication by shaping a fluid or plastic raw material with the help of a rigid framework known as a mold. There are lots of mold sellers, and their products are not the same in terms of quality. In order to acquire the best mold set, there are tips you should be keen on. You need to keep reading to learn more.The structure is the first thing you should consider. Of late, not every person who acquires molds has complete knowledge regarding plastic injection molds.

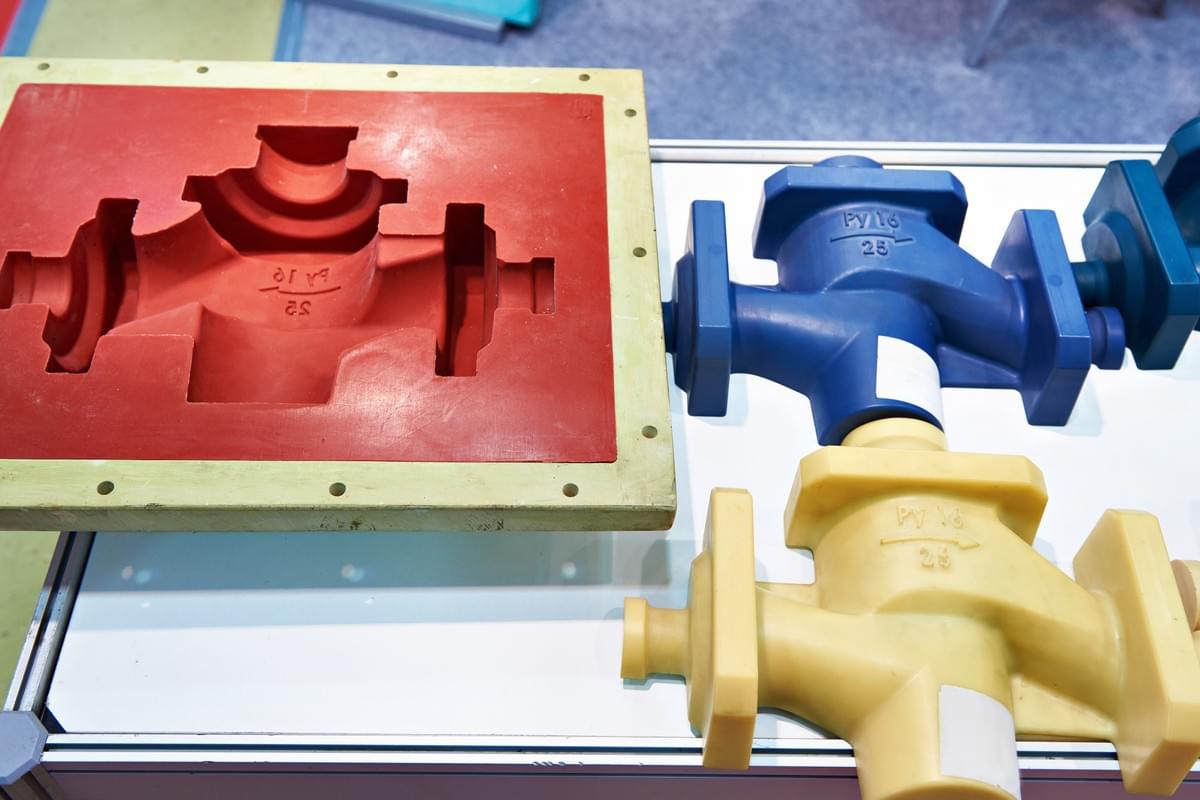

Only people who have been in this sector for a long time are acquainted with how injection molds should be constructed. You need to know that a plastic injection mold is an item of specific standards. Even though mold construction is regulated and used around the world, every machining tool can get refined to work best for various products. Every set of molds is essentially a cooling water system, a mold plate, product company, a guide, a battery returning spring, and a positioning system. It is necessary that you put the material into consideration. Customers usually put the cost into account but fail to be keen on the product material.

However, you are supposed to be extra careful as you can cut costs and get useless products. To avoid frustrations, you should work with a regarded seller. Be sure to check the seller's carbide tooling process. This owes to the actuality that you will find sellers who claim that their materials stand out in quality. This way, you will be sure you are acquiring molds of the original material. Additionally, these employ severe quality control standards that assure materials are of awesome quality. You need to settle for flexible – safe operation. You should not look at Beauty alone but give priority to durability as well as safety. When your mold is finished and going through the acceptance test, you need to look directly on the injection molding machine in order to see how the mold operates, is it safe?

The system is supposed to work smoothly, efficiently, and quietly return to the right position. The positions are displayed with a pin guide, placed to fit together to provide a seamless experience when locking and unlocking the mold. When opening and shutting, the mold must not create a too loud noise. Lastly, consider ordering from a seller who stocks a range of molds. Molds come in a range of types, for example, compression molds, extrusion molds, injection molds, compression molds, and rotational molds. In case you consider ordering molds from a supplier with a limited range of products, he or she might urge you to acquire the wrong products. Visit https://en.wikipedia.org/wiki/Injection_moulding for more insights about the molding and casting process.